For a circuit guy – like myself – I think what the saying is really trying to tell you that AC-DC adaptor with transformer built in is better. For this I can’t agree more... from low level signal perspective.

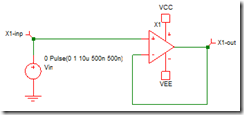

For a +5V AC adaptor without transformer – each and every node inside the adaptor circuit is considered “LIVE” which means it is dangerous – the AC outlet voltage 230V for example is directly switched by silicon IC, and filtered to give a output of +5V. See schematic below:

(picture from some online forum.. sorry that can’t remember where I got it exactly, been with me for some time)

For a +5V AC adaptor with transformer – generally the transformer will scale down the line voltage to much managed able 12VAC or so, before passing it through bridge rectifier to and further drop down to +5V. So the secondary side of the transformer is not “LIVE” and much safer to mess around. Note that since the switching is done at much lower voltage level – the electrical noise will be much less. As shown below:

There are considerations on which is better – costing, how “clean” it is..., eventually it is up to the application and individuals to decide. For me, when I build something that requires mV or nA level of accuracy – those with transformer are definitely my choice of adaptor. Other than that, it does not bother me much.

I guess at the end of the day, knowing the fundamental of different AC adaptors allow an engineer to decide what is good enough for the application, and this especially important when dealing with low level analogue signals.